Capabilities

Our experienced engineering team listens and delivers innovation you can count on.

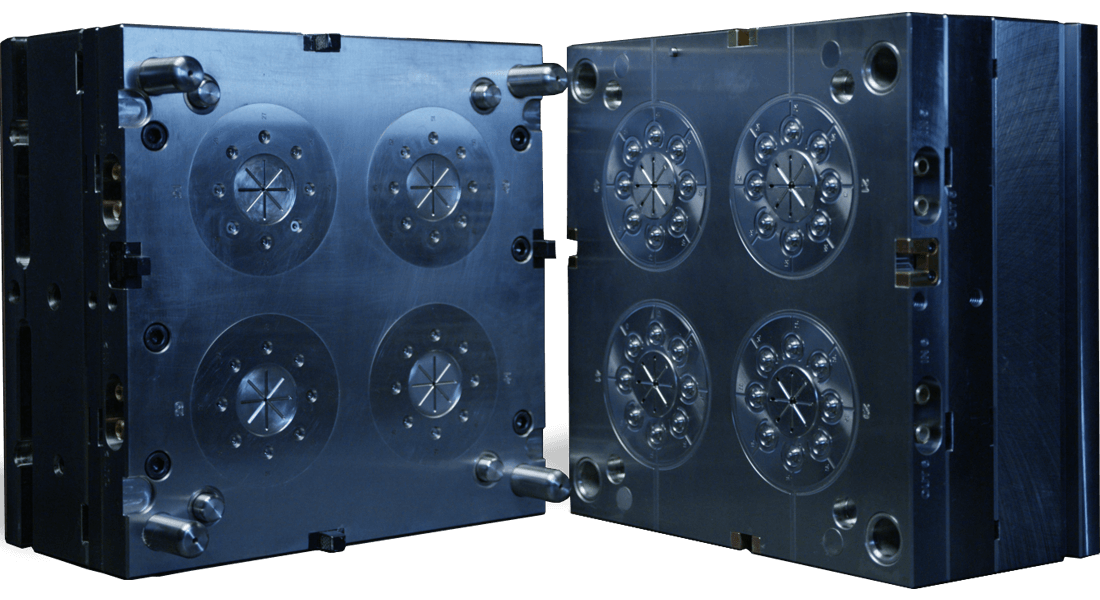

Mold Engineering

Our mold engineering capabilities are simply unsurpassed. Standard components, quality materials, proven mechanisms and the use of the latest in CAM technology are the core principles of our mold engineering capabilities. All molds are desgined in 3D solids, which are then used in the programming and machining operations of our CNC department.

From design and mold building or repair to mold testing, on-time delivery and even turnkey production, our vigilant program management supports your tooling program’s success.

Our program management staff, domestic and offshore, provides a direct line of communication to our design team, engineers, toolmakers and process technicians.

We monitor time frames and quality control to provide you with the tool that meets your production schedule and expectations.

The making of a mold is not complete until the mold is operating satisfactorily in the injection molding process.

All of our tools are put to the test using our electric molding machines to debug and qualify the mold and molding process. This way, you can be sure that when your mold arrives at your facility, it is ready to run.

Product Design

Our expert engineering capabilities give you the support you need at the all-important first stages of your project to avoid delays and reduce costs. And with our full capabilities, we can continue to support your project through completion.