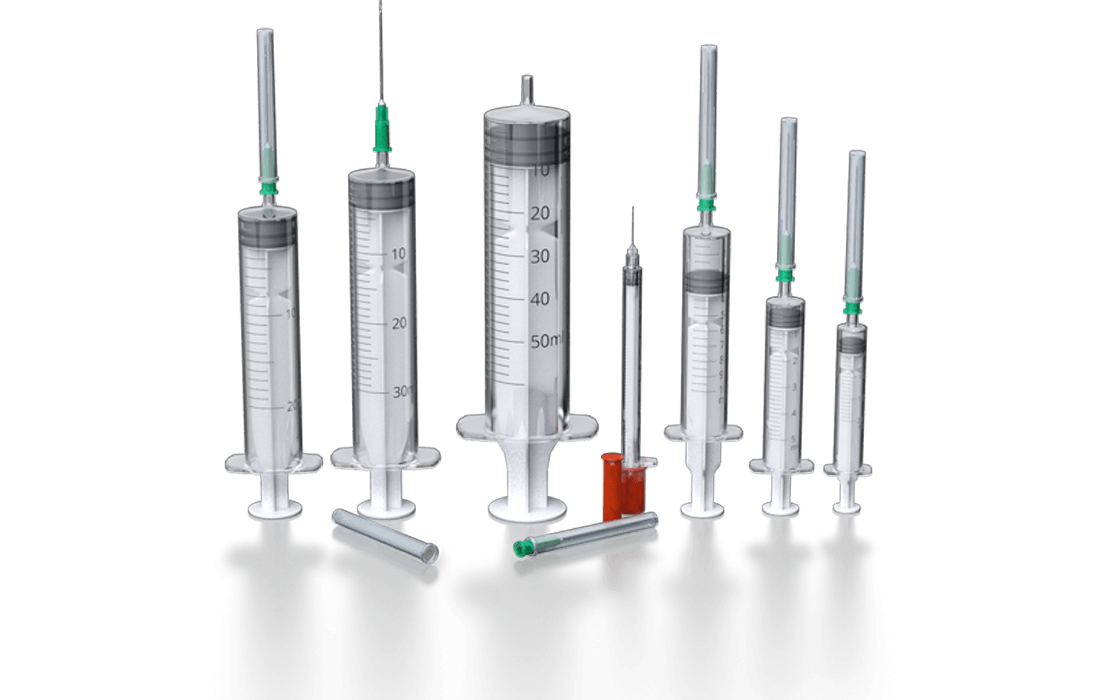

We understand the exacting specifications required for medical applications and FDA compliance. Our extensive experience working with leading medical manufacturers includes ISO 8 clean room injection molding capabilities. We provide a repeatable process to ensure you receive the same part, every time, with no variances.

Sensitive electronics and fiber optics applications demand precision parts that align accurately. Rapid has been delivering tight-tolerance solutions for electronic components, assemblies and devices since 1997. We are experts at working with fiber optics tolerances.

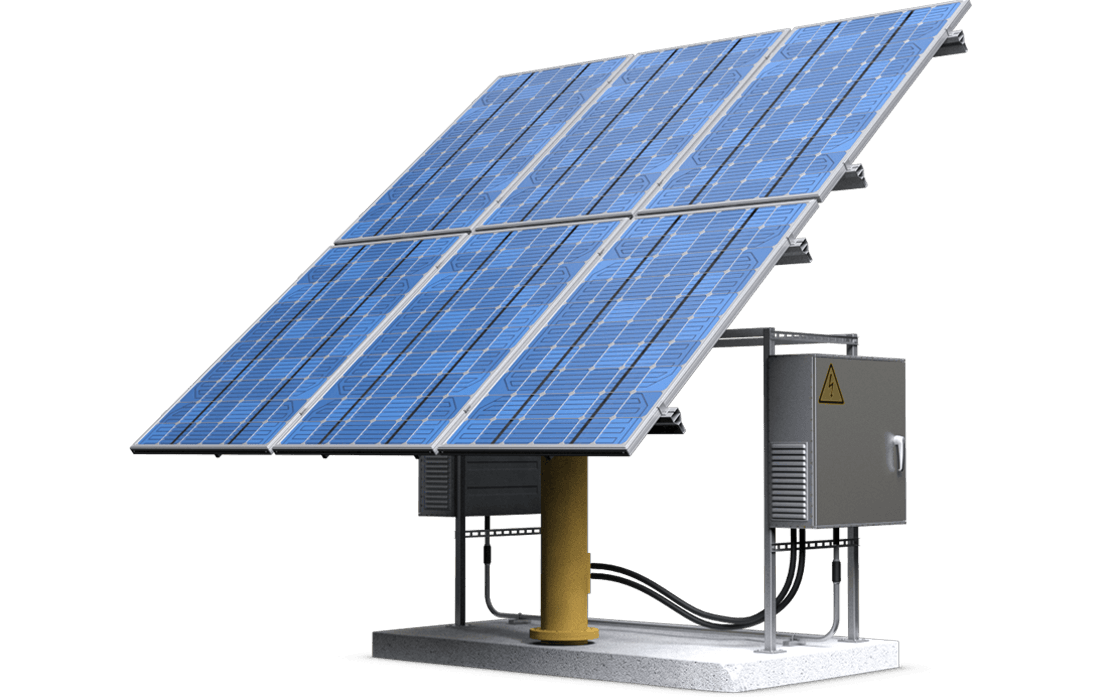

Part of what we do best is understanding your exact needs and end goals. That’s why our engineers, toolmakers, machinists and plastic injection molding experts are trusted by leaders throughout the irrigation field. We are proud to bring value to major industry brands by delivering exceptional sprinkler parts at the right price point.

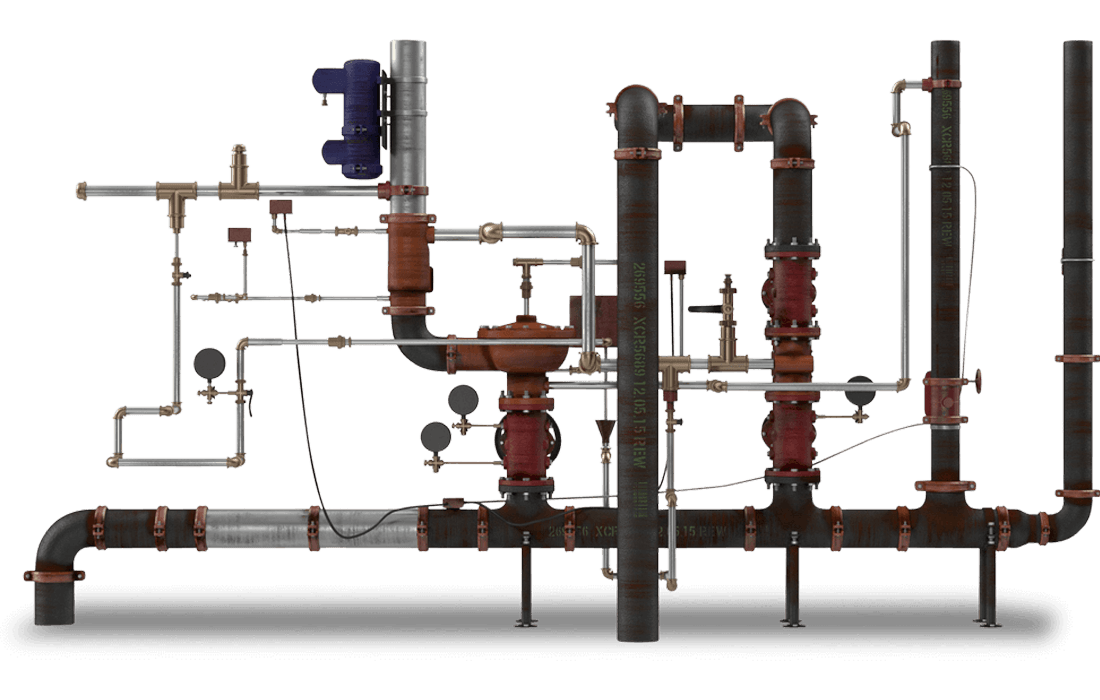

In an industry that’s always progressing and innovating, time to market (TTM) is of the essence. Our workmanship and expertise mean your tooling and plastic injection molding parts are done right — and on time. From complex to basic tooling and parts, we’re ready to serve your needs.

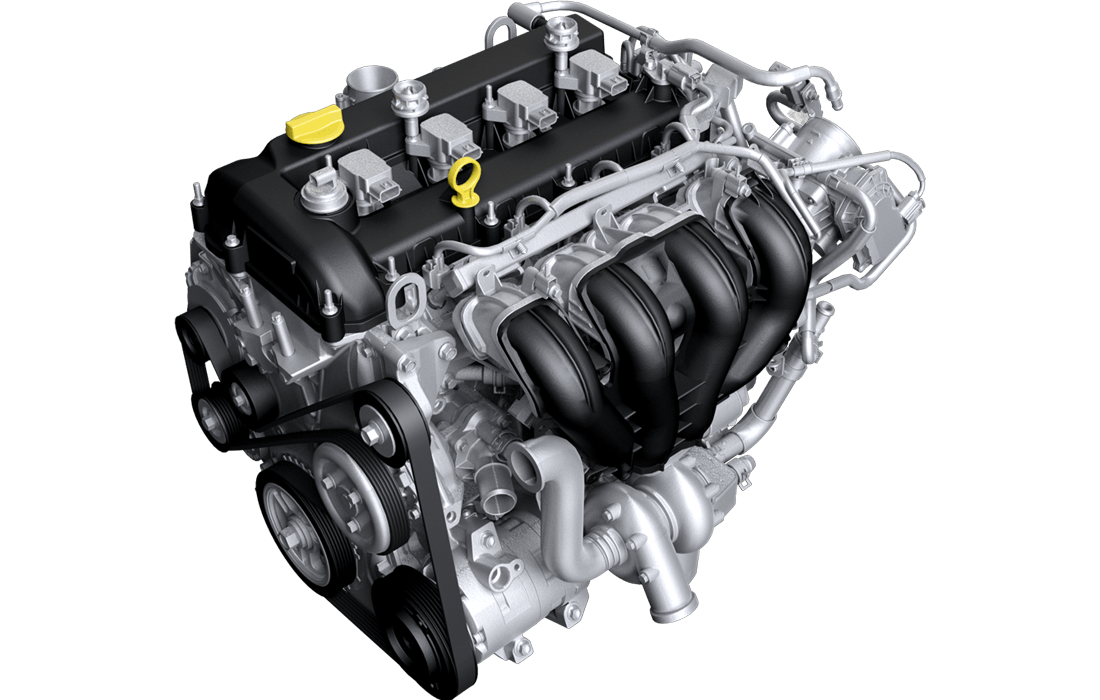

We partner with some of the biggest brands in the transportation arena to deliver engineering, tooling and production that helps drive performance. From design to delivery, we manage your project with smooth, confident efficiency. Rapid Production Tooling is backed by the strength of our parent company, RL Hudson, a leader in manufacturing parts and assemblies for engines.

Leading OEMs in every kind of space bring us their high-spec challenges. We can support your next project, too. Our engineers will work with your design team to avoid pitfalls, optimize your program management, and hit your critical delivery dates. We get it right the first time — yet another reason we’re known for our 99.9% on-time rate.